Welcome to the official website of Jinzhou Heli Vacuum Metallurgy Co., Ltd!

Email:qj7900@163.com

Service Hotline:+86 416-4185882 +86 13804167900

Three-chamber vacuum melting furnace Vacuum melting furnace Vacuum atomization powder making furnace

Medium frequency melting furnace

Category:

Keywords:

Medium frequency melting furnace

Hotline:

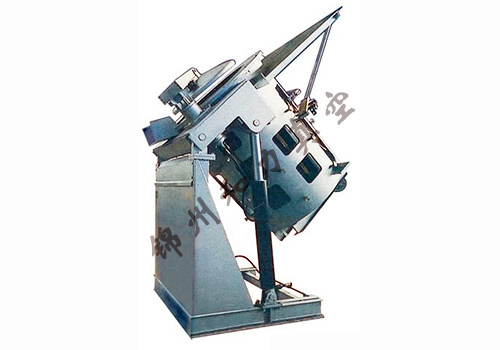

Medium frequency melting furnace

Induction heating is performed using a 200-1000Hz medium-frequency power supply with a power range of 100-6000kW, mainly used for smelting steel and cast iron, but also for smelting and heating, and heat preservation of non-ferrous metals such as copper and aluminum.

1. Scope of medium-frequency melting furnace sets:

1.1 Medium-frequency power supply and electrical components: Power supply equipment includes high-voltage or low-voltage switchgear, medium-frequency power supply, power conversion switch, compensation capacitor, and medium-frequency control cabinet, etc. Large medium-frequency furnace electrical components also include crucible leakage furnace alarm system.

1.2 Furnace body: Medium and small medium-frequency furnaces are equipped with two furnace bodies. One is used for production, and the other is a spare. The furnace body includes the furnace cover, inductor, crucible, furnace body support (steel shell furnace is divided into fixed support and movable support), etc.

1.3 Transmission device: The transmission device includes mechanical or hydraulic devices such as the movement of the furnace cover and the tilting and resetting of the furnace body.

1.4 Water cooling system: Water-cooled parts include: medium-frequency power supply, inductor, capacitor, and busbar, soft cable, etc. In order to save water, a circulating cooling method is usually adopted.

2. Features of medium-frequency melting furnace:

2.1 Small equipment size, light weight, high efficiency, low power consumption.

2.2 Low temperature around the furnace, less dust, good working environment.

2.3 Simple operation process, reliable melting operation.

2.4 Uniform metal composition, good material control.

2.5 Fast melting and heating, easy furnace temperature control, high production efficiency.

2.6 High furnace utilization rate, convenient variety change.

3. Classification of medium-frequency melting furnaces:

Capacity from 100g to 5T (based on steel); equipment can be customized according to user requirements.

Inquiry

Related products